With wind and solar booming, researchers are looking for ways to turn electricity into other products, to cut carbon and integrate renewables into the power grid. Power-to-X could go a long way towards these goals, says Ben Paulos.

Power-to-X turns surplus electricity into hydrogen, chemicals, heat, and other useful products (Public Domain)

Because wind and solar are driven by nature, there are times when they produce more or less energy than is demanded.

It turns out that managing their hourly or even daily fluctuations are not a big deal. Grid operators have seen days with more than 60% wind power in the US Midwest or 85% total renewables in Germany. Grids already have a certain amount of flexibility – they can turn fossil and hydropower plants up and down; they can import or export power from their neighbors; or they can pay their customers to use less power.

But variations by season can be a bigger problem, especially without using a lot of fossil fuels.

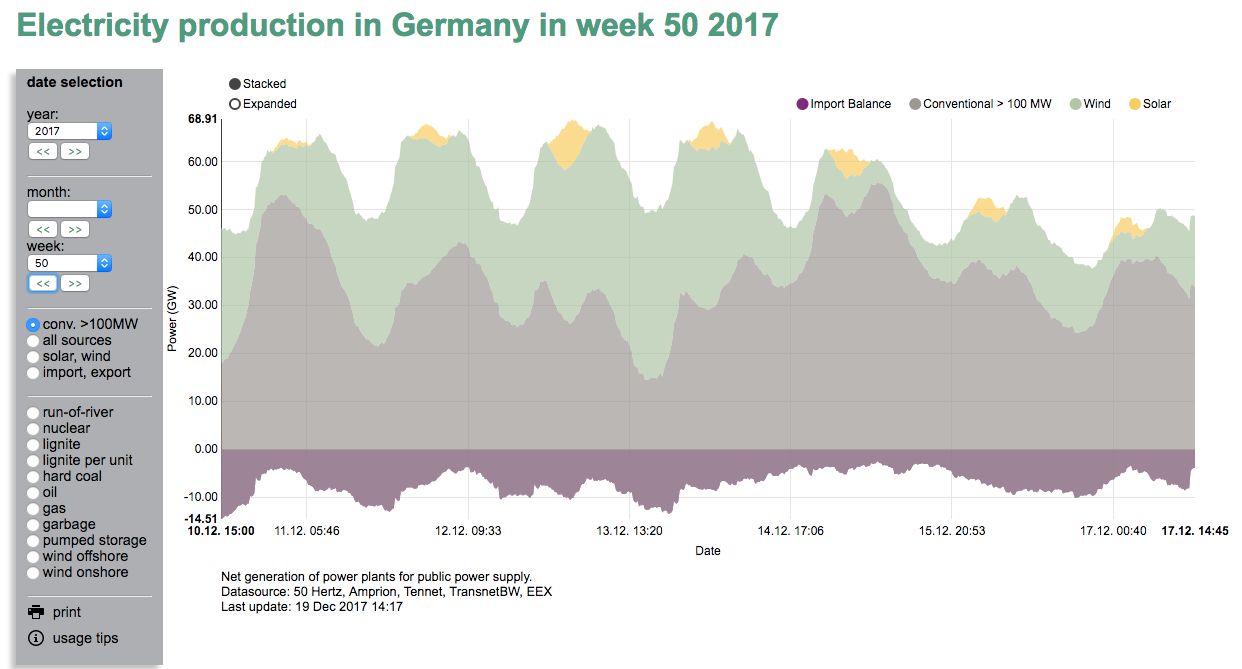

Germany is a vivid example. With the same latitude as Alaska, the winters are dark in Germany, and solar power dwindles to near nothing, as shown in the chart from Fraunhofer Institute. Fortunately, winters also see brisk winds blowing off the North Sea, delivering large amounts of wind power.

Source: Fraunhofer Institute

With lots of solar panels in the south and wind turbines in the north, this makes the north-south transmission expansion currently underway critical to making renewables work in Germany. Still, running the country on just one or few fuel sources is risky. And if Germany is to phase out fossil and nuclear fuels, it will need something else to make up for seasonal shortfalls in wind and solar output.

Power-to-X

Energy storage is an obvious answer to a system with no fossil fuels, but most storage technologies on the market now have a very short duration. The lithium-ion batteries that power electric cars work on the time scale of hours. Pumped hydropower, where water is pumped behind a reservoir and then released through a turbine, works on the scale of days or weeks, typically.

If the goal is to shift abundant summer solar power into the dark winter nights, something very different is needed.

In some cases that means electrification, converting other sectors to electricity to help soak up that abundant wind and solar power. Regulators and stakeholders from Germany and California recently met to discuss how to displace fossil fuels by using renewable power in electric vehicles, heat, and other industrial applications.

But researchers are starting to look beyond, at ways to convert electricity to longer-lasting and storable products. This emerging suite of technologies and strategies goes under the banner of Power-to-X.

Power-to-X turns surplus wind and solar electricity into hydrogen, chemicals, heat, and other useful products. There are at least 18 power-to-gas demonstrations underway in Germany with more in the works, according to the European Power to Gas Platform.

The X getting the most attention is hydrogen. Electricity can be used to split water (H2O) into hydrogen and oxygen, a technique known as electrolysis that dates back to 1800 and is well known to even grade school students.

Hydrogen can then be used in fuel cells, gas turbines, or engines to make electricity, or can be used as a feedstock in synthetic natural gas or other chemicals. Hydrogen can be mixed with natural gas and stored in natural gas pipeline and underground storage systems. Existing gas systems in Europe can hold 12 times more energy than current pumped hydro systems.

The consulting firm DNV GL, writing in a paper for the European Power To Gas Platform, says the transportation sector is especially key in commercializing power-to-X technologies. Honda and Toyota are both selling passenger cars that run on hydrogen, while a variety of ships, buses, planes, and industrial vehicles are experimenting with hydrogen fuel cells.

But while electrolysis technologies are well known, they are currently a significant cost barrier to producing renewable hydrogen. “For many of the above mentioned functionalities of power-to-gas there is currently not yet a business case,” DNV writes. “Significant cost reductions and efficiency improvements are required to enable its deployment on commercial scale.”

The Power-to-X Alliance, composed of Audi, Airbus, and other companies, proposed legislation in Germany in November that would help commercialize power-to-X technologies, with incentives based on tons of carbon avoided.

Power to Eggs

Europe is far ahead of the US on power-to-X, where it is still largely considered an exotic concept. But one innovative project is exploring the potential for wind power to improve farming practices.

The University of Minnesota at Morris formally dedicated a project in 2013 to start using wind power to make synthetic fertilizer for farming. Producing nitrogen-based fertilizers accounts for roughly 40% of the energy that goes into producing corn, increasing the carbon footprint of meat, dairy, and ethanol. Moreover, nitrogen is itself a potent greenhouse gas. When it emits from the soil in the form of nitrous oxide (N2O) it has a global warming potential almost 300 times that of CO2.

Because air is 78% nitrogen, researchers in Minnesota are able to use wind-powered electricity to pull nitrogen from the air and to split water into hydrogen.

“We have core constituents of anhydrous ammonia which are nitrogen gas and hydrogen gas,” explains Michael Reese, renewable energy director for the project. “And then we use the standard Haber-Bosch process to produce nitrogen fertilizer.”

The Haber-Bosch Process, developed by two German scientists in the early 1900s, was key to creating the large amounts of low-cost fertilizer that enabled the explosion in farm productivity in the 20th century, known as the Green Revolution.

University of Minnesota graduate Norman Borlaug developed varieties of wheat in the 1940s that could thrive on the synthetic fertilizer. He won the Nobel Prize as the “father of the green revolution” and is credited with the food production that saved one billion lives across the globe.

“Today, the problem is more complex,” according to the University. “We need to produce significantly more food AND use clean energy while protecting the environment for future generations.”

“In the spirit of Dr. Borlaug, our research team is striving to meet the grand challenge of feeding the world and sustaining the environment through a Green Nutrient Revolution.”

Below is a video explaining the German Government’s energy targets, and what role Power-to-X can play.

»Energy storage is an obvious answer to a system with no fossil fuels«

No, it is an obvious answer to a system with NO fuels. And there are fuels which are not fossil fuels. And most importantly, fuel is storage (of energy). Don’t forget that natural gas is fossil fuel (common theme in “renewables”).

So, the main proposal is obtaining hydrogen FUEL for storage using electricity generated by renewables. This system will create fuel with the help of electricity FROM wind (/solar) power (not directly from WIND power as it stated) – the basis is electricity and it can come from multiple sources. And oh, hydrogen will be produced via electrolysis, very inefficient process. Electrolysis can be much more efficient with high temperatures (800°C+). But to reach that temperature and heat you need a lot of electricity (and that will be the only form of energy produced by wind/solar e.g. renewables, right?).

And there it is – plan to convert electricity to heat “Power-to-X turns surplus wind and solar electricity into hydrogen, chemicals, heat, and other useful products”. And now heat is regarded as useful product. Converting electricity to heat is not a “green” idea and is a crime in regard to entropy generation.

With renewables you get electrical energy and some heat (result of friction), this heat cannot be harvested. You only get X (unit of) electrical energy. By proposed plan this electricity is converted to heat, used for electrolysis etc. Electricity to heat conversion is nonsense, you are converting high exergy (quality) energy to very low exergy (low quality) energy. And conversion factor is 1 (resistor heating), with usage of heat pumps can be 3 – so for every 1 unit of electricity you gain 3 units of heat (but low temperature: for effective electrolysis we need high temperature).

I suppose the heat produced by this system will be mostly used in households and as industrial heat, since 60% of ELECTRICITY produced is converted to heat (for heating resident buildings, water heating, industrial heating etc.). But this is nothing new, it’s called district heating.

Let me introduce you to the thermal power station. Yes, it runs on fuel (so would renewable energy system, only it represents itself as storage). The fuel is converted into heat and heat is converted to electric power with efficiency 35%. Byproduct is excess heat, which is often times discarded into environment (water vapor). For every X of electrical energy, there is 2X of excess heat.

If this heat is properly harvested (cogeneration) and then there can be LESS electricity converted to heat: every unit of heat provided, is unit of electricity saved. Such cogeneration cycles have efficiency up to 80%+ (oppose to only 35% with conventional thermo). See the difference? Here you get the heat, you don’t need to convert electricity to heat. As I stated, we can convert electricity to heat with factor up to 3.

But with themo power plants, for every 1MW of electricity LESS produced, we get 10MW of MORE heat (so ratio 1:10), I don’t know, how much % of it can later be used. And ofc at the times of excess energy, this electrical energy can too be used for electrolysis in combination with heat (more efficiently), but with thermo power plants you can predict supply/demand more precisely.

And the type of thermo power plant: ofc go nucelar and get co2 free (that’s the goal, right?).

I am talking about systems that already exists and are ready for deployment, no need for wishful thinking/dreaming and speculating. Here, now.

And since we are here and gazing into the future and thinking of the possibilities:

Finland eyes nuclear district heating http://www.world-nuclear-news.org/NN-Finnish-cities-consider-SMRs-for-district-heating-1512175.html

China looks to nuclear option to ease winter heating woes https://www.cnbc.com/2017/12/10/china-looks-to-nuclear-option-to-ease-winter-heating-woes.html

And with fast reactors, gen 4, waste is no longer a problem (maybe that’s why Russia is so keen on handling nuclear waste of abroad reactors – use spend paid fuel and take handling fee)

Russia transition to Fast Reactors http://www.world-nuclear.org/information-library/country-profiles/countries-o-s/russia-nuclear-power.aspx#ECSArticleLink3

China begins building pilot fast reactor http://www.world-nuclear-news.org/NN-China-begins-building-pilot-fast-reactor-2912174.html

Future of floating nuclear power plants (for remote/energy deprived locations) and icebrakers:

http://bellona.org/news/nuclear-issues/nuclear-russia/2018-01-russia-official-announces-plans-to-build-space-age-nuclear-icebreakers

https://en.wikipedia.org/wiki/Nuclear-powered_icebreaker

China plans further high temperature reactor innovation

http://www.world-nuclear-news.org/NN-China-plans-further-high-temperature-reactor-innovation-1909171.html

Nuclear Process Heat for Industry http://www.world-nuclear.org/information-library/non-power-nuclear-applications/industry/nuclear-process-heat-for-industry.aspx

SMRs etc…

Yes, this is in progress now, maybe someone will provide links to “what-if” future of nuclear (must be only good news, this is after all, a positive post)

The future is not in utilizing multiple inefficient processes only because we want wind/solar to be the main driver.

“Honda and Toyota are both selling passenger cars that run on hydrogen..” The top-selling FCEV, for practical purposes the only one, is the Toyota Mirai. As of February 2017, 2,840 had been sold. Production is running at 3,000 a year according to Toyota. Sales of electric cars in 2017 were a round million, according to BNEF. This boat has sailed. The fuel-cell route adds a conversion layer and losses, and requires an expensive new distribution infrastructure. Battery EVs are already getting the economies of scale, so FCEVs cannot catch up. Fuel cells are successful in the niche of fork-lift trucks in warehouses, and have promise for ships.

The principal competitor to P2G is overbuild and planned curtailment. In a high-latitude country like Germany, this means both wind and solar, with surplus output of solar in summer and wind in winter. (That assumes diurnal variation is met by storage, and the surplus is after meeting it). As it happens overbuild creates a large supply of near-free electricity available for P2G, so the approaches are complements as well as substitutes. The optimum mix will depend on relative prices.

Hydrogen is by no means limited to passenger cars, though, James.

The big energy users that are impractical for battery electricity like cargo shipping, commercial airplanes and months-long seasonal storage for electricity generation in the Nordic countries (watching the Scandinavian Noir series’ like The Bridge made me super-aware of their literally months of darkness!) are all much bigger targets for decarbonizing with hydrogen. I’m excited about all the thermochemical research into making hydrogen and solar fuels using solar heat.

The University of Minnesota won a best paper award for

“The morphological stability and fuel production of commercial fibrous ceria particles for solar thermochemical redox cycling”

http://dx.doi.org/10.1016/j.solener.2016.10.029

“University of Minnesota Solar Energy Laboratory demonstrated continuous fuel production from a 4 kW prototype solar thermochemical reactor operated in Minnesota’s indoor solar simulator over 140 hours. The reactor is the first to produce fuel continuously on-sun and to recover over 90% of the sensible heat of the working gases.

This research uses a solar reactor for making hydrogen with thermal solar driving the chemistry, rather than PV+electrolysis.